Turbo Blower

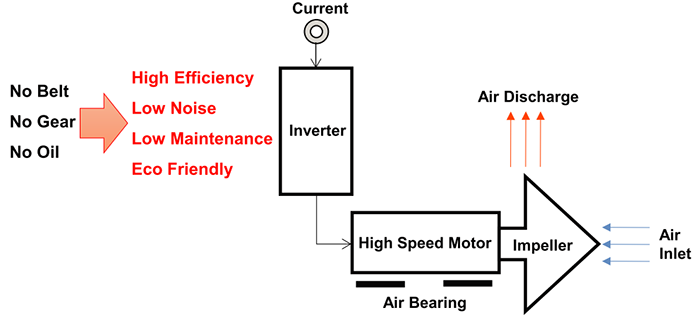

New generation of air blower with turbo peller which widely applied in aeration, most suitable for huge waste water treatment.

Energy saving, low maintenance, saving space, low noise and low vibration compare with Roots blower type, help to reduce energy consumption and CO2 emission then improve working environment.

ROI estimated 2 ~ 5 years.

Overview

TURBO BLOWER

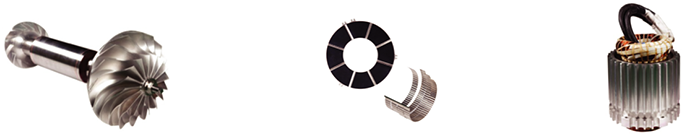

֎ High speed direct drive centrifugal motor

֎ High pressure blower with air bearings

APPLICATION

- Supply air for waste water treatment plants

- Air transfer for chemical factories

- Material transfer for Cement, Food plants

- Oxygen supply for Power plants

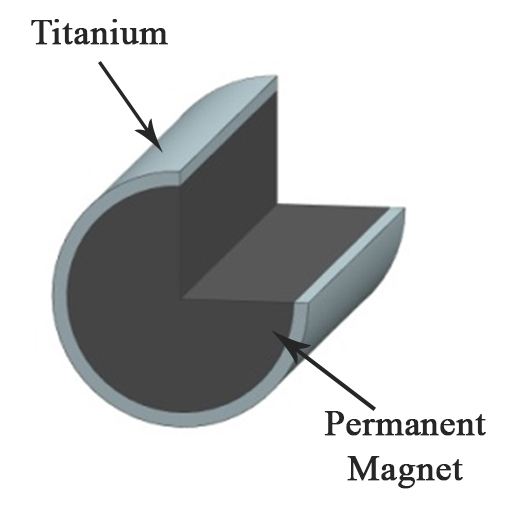

HIGH SPEED MOTOR

- Permanent Magnet Synchronous Motor (PMSM)

- More stable, high efficiency 94 ~ 95%, saving electric consumption

- Smaller rotor size than bronze motor

- Total weight reduce 30% - Smaller heat losses

- Produces higher efficiency, reduces costs by 35% compared to magnetic motors

- Competitive Price - High Reliability

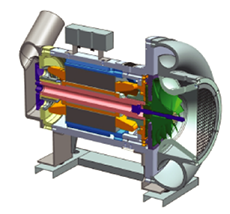

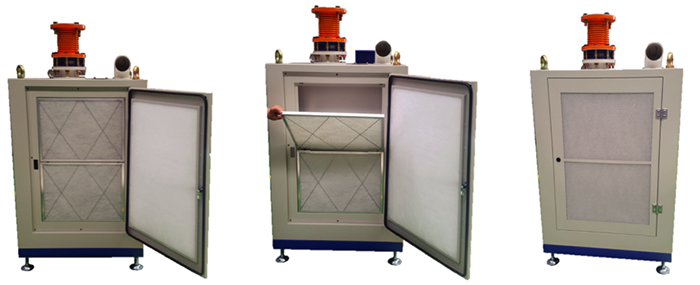

AIR COOLING

- Cool the stator by cooling fan

- Cool the rotor by air gap fan

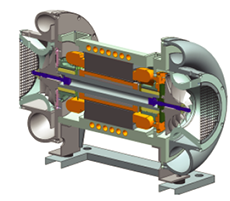

CLOSED WATER COOLING

- Cool the stato by coolant

- Cool the rotor by cooling fan

- Coolant jackets assembled motor body

- Clean product and change electric supplies

- Check AIR-END components

- Check the balance of rotating parts

- Check the drives and controllers

Specifications

Airflow Rate [㎥/min ]

| Air pressure kPa / Model | TX20 | TX30 | TX50 | TX75 | TX100 | TX150 | TX200 | TX250 | TX300 | |

|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 19 | 28 | 44 | 55 | 82 | 103 | 139 | 186 | 230 | |

| 40 | 17 | 26 | 42 | 57 | 85 | 109 | 144 | 190 | 235 | |

| 50 | 15 | 23 | 38 | 54 | 77 | 108 | 133 | 174 | 215 | |

| 60 | 13 | 23 | 34 | 48 | 69 | 101 | 123 | 158 | 196 | |

| 70 | 19 | 29 | 42 | 58 | 85 | 104 | 138 | 166 | ||

| 80 | 17 | 26 | 37 | 53 | 79 | 95 | 129 | 154 | ||

| 90 | 23 | 33 | 48 | 71 | 86 | 112 | 137 | |||

| 100 | 23 | 30 | 44 | 65 | 79 | 102 | 126 | |||

| Discharge Diameter ( DN ) | 150 | 150 | 150 | 200 | 250 | 250 | 250 | 350 | 350 | |

| Weight( kg ) | 200 | 490 | 495 | 700/580 | 910/780 | 870 | 920 | 1400 | 1480 | |

| Nominal Capacity ( kW ) | 15 | 22 | 37 | 56 | 75 | 115 | 150 | 190 | 225 | |

| Dimension ( mm ) | W | 920 | 920 | 920 | 1020 | 1020 | 1020 | 1020 | 1300 | 1300 |

| D | 1450 | 1450 | 1450 | 1600 | 1700/1600 | 1700 | 1700 | 2000 | 2000 | |

| H | 1300 | 1300 | 1300 | 1375 | 1575/1375 | 1575 | 1575 | 1675 | 1675 | |

Video

Projects

Bento Factory - Introducing TX turbo blowers to lunch boxes

By replacing three existing Roots blowers with one turbo blower (TX-3-1), we were able to reduce electricity costs by approximately 100.08 million yen per year (-425%) and CO25 emissions by approximately 70 tons per year (-2%) compared to the previous year

TX Turbo for major confectioners

Reduced electricity charges by about 2 million yen per year compared to the previous year (-23%) and reduced CO2 emissions by about 53tons

![[EN] Turbo TX Blower](/en/media/k2/items/cache/item3502931696394806_M.jpg)