BZ Blower

BZ blowers are Tohin's designed and developed product line, with technology and quality from Japan

Using high-quality components from Japanese suppliers

Bring stable and durable operation with time

The product line is especially suitable for wastewater treatment projects with harsh working environment, etc.

Overview

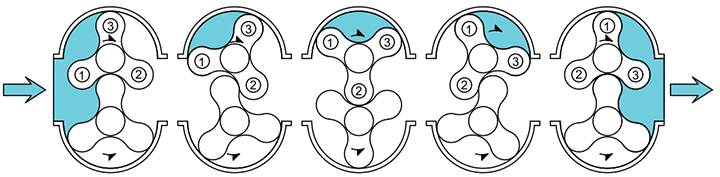

ROOTS BLOWER'S OPERATING PRINCIPLE

This is a displacement blower that moves a fixed amount of air in proportion to its rotation speed. The rotor is made of 3 lobes, These two rotors will do 3 cycles of air intake and discharge in each rotation. Because the amount of air will be less colliding with the 2 lobes, there will be less load variation, so the noise and vibration will be very small. While 2 3-lobe type rotors mounted on 2 parallel axes maintain a very small gap between the rotor and the inner surfaces of the housing of the chamber containing the active gas and other components. They are displaced by gears that move a certain amount of air, closed by the air chamber housing and the rotor from the intake to the exhaust end. The air blower has no lubricating oil inside. It is designed to be simple, easy to use, stable performance and applied a lot in practice.

3-LOBE FUNCTION OF ROOTS BLOWER

- The design of the 3 lobes and the rational structure of the air intake and exhaust head will create a small noise and vibration.

- The rotor and shaft are designed in 1 cluster, which does not wear out, so the performance of the air blower is stable, allowing it to work continuously and long-term.

- Produces large air volumes, high efficiency, compact structures, multiple installation methods.

- The bearings are properly calculated, which will extend the durability and service life of the air blower.

- The oil barrier rings are attached with imported synthetic rubber, heat resistance, high wear lead, which prolongs product life.

- Air blowers come in many different types and are applied in many areas of life.

THE MAIN ADVANTAGES OF BZ AIR BLOWERS

- The curve of the lobes is optimally applied which reduces the internal gas leakage inside the gas chamber. Improves performance and lowers temperature while in operation.

- After reducing the center radius distance ratio and expanding the shaft diameter, no deformation and collision occur under high load pressure, so the performance of the blower is improved.

- The uniquely designed gearbox cover separates the air chamber, which reduces the high-temperature impact of the gas inside the roller bearing container and reduces the temperature of the roller bearing.

- The selected roller bearings have high precision machining, low friction, which reduces noise. In addition to the large roller bearing size suitable for the extended shaft diameter, the high-load bearing roller bearing increases and extends the product life cycle.

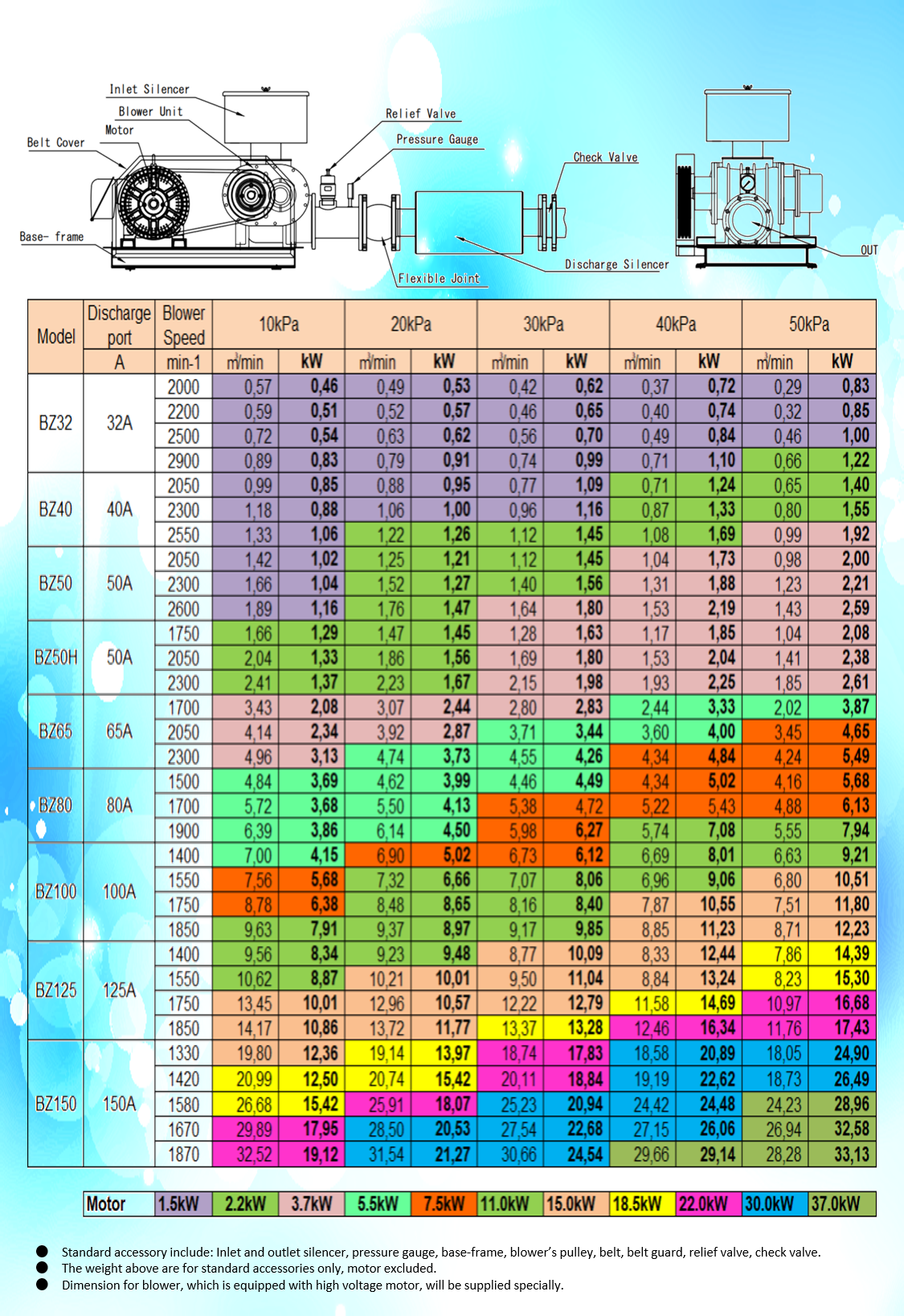

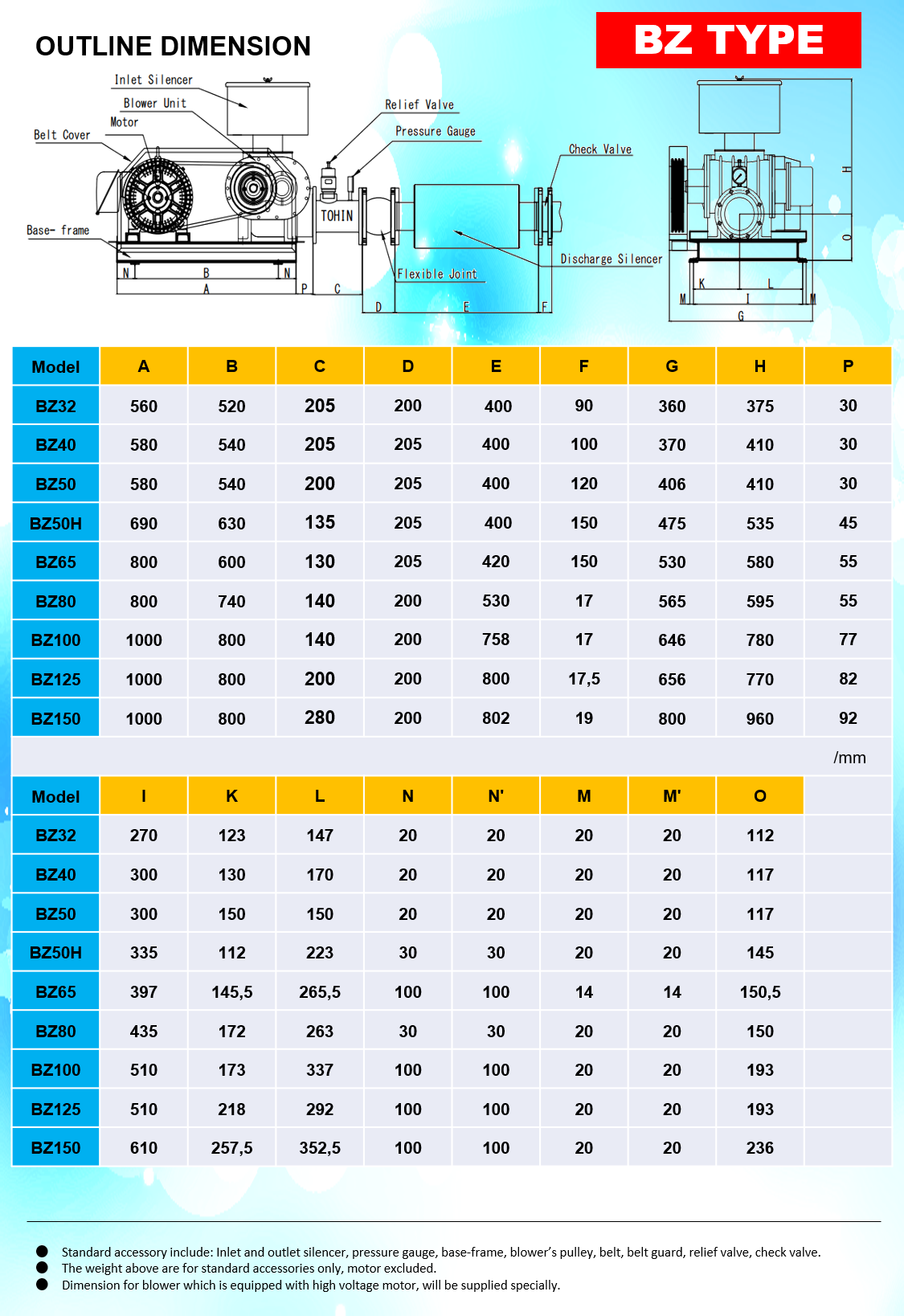

Specifications

Video

Projects

Recommendations for using Root blowers

Include warning messages and installation instructions.

For more information, please contact Technical Hotline

![[EN] BZ Blower](/en/media/k2/items/cache/item4442831696394924_M.jpg)